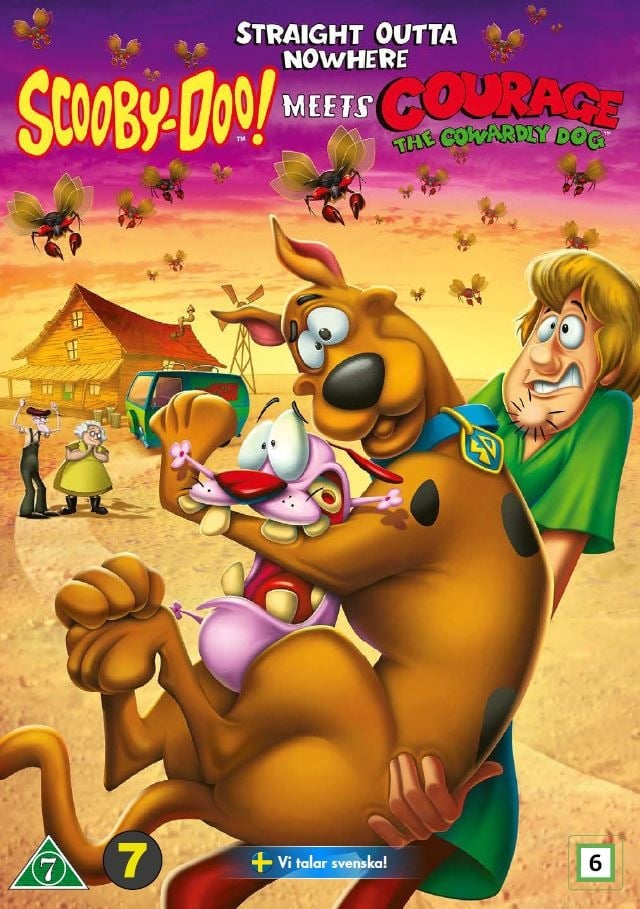

Frygtløs - Den frygtsomme hund! - Hvis du har Netflix kan du nu se Frygtløs - Den frygtsomme hund! på dansk! UGA BUGA BUGA! | Facebook

Hundelæge Le Quack Television Courage, Kandy, Tegneserie, mod, frygtløs den frygtsomme Hund png | PNGWing